RLT-P200 is a high-performance, water-soluble corrosion inhibitor designed for superior rust prevention in machinery manufacturing and maintenance. With excellent water solubility and a transparent solution, it provides long-lasting protection for ferrous metals, including cast iron, carbon steel, and alloy steel, without leaving residues.

RLT-P200 is a high-quality and high-efficiency water-soluble corrosion inhibitor. The product has excellent water solubility, transparent water solution and excellent rust resistance. It is suitable for anti-rust of ferrous metals in the process of machinery manufacture and maintenance, semi-finished products and finished products. It is suitable for iron series materials such as cast iron, carbon steel and alloy steel. iron materials.

Features and benefits

● Strong rust resistance, good protection for ferrous metals at low concentration.

● Good water - soluble, can be mixed with water in any proportion.

● Low residue, easy to clean by water - based cleaner or solvent cleaner.

● Good adaptability to hard water.

● Waste liquid treatment is convenient and environmentally friendly.

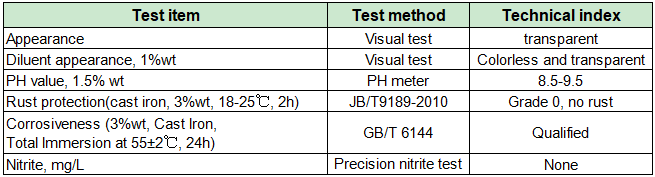

Typical physical and chemical properties

Application

Water miscible metal working fluids (synthetic and semi synthetic MWF)

- Metal working emulsions and solutions (for tank-side addition)

- High water based hydraulic fluids (type HFC)

- Water-based metal cleaning concentrates

- Metal cleaning solutions (for tank-side addition)

Usage

1. Recommended concentration: 3% - 5%. The use concentration can be adjusted appropriately according to the requirements of rust prevention.

2. Working temperature: normal temperature can be used, heating can improve drying efficiency, but do not boil, otherwise the concentration changes greatly.

3. Treatment time: soak for 2-5 minutes, spray for 2 minutes.

4. Before processing: before rust-proof treatment, the workpiece needs to remove the original rust, otherwise it will affect the effect of rust-proof.

5. After processing: the workpiece drying or natural drying that the formation of rust film.

6. After anti-rust treatment, rain water or other liquids should be prevented from contaminating, so as to avoid the failure of anti-rust.

Contact: LilyLu

Phone: +86 138 2603 0637

E-mail: lilylu@rolitom.com

Whatsapp:+8613826030637

Add: Room610 NO.1 XiangPu Street,TianHe District,Guangzhou City,china

We chat