RLT-8850 is a stable,water based emulsion, which is ideally suited for the conventional and slightly reduced spray application and even for low-volume spraying (micro-spraying).The reason is the careful selection of certain raw material combinations, ensuring not only the high quality of produced castings but also the problem-free handling of the castings in downstream processes.

Castings are clean, bright and are readily painted or coated and are also suitable for welding or gluing.

The release agent raw materials have good batch stability.The production adopts automatic vacuum emulsification equipment technology. The whole process uses deionized secondary reverse osmosis purified water, and the molecular diameter after emulsification is uniform. Because the pure water in the raw materials does not contain minerals, so the product has excellent carbon deposition resistance and will not form residues on the mold surface after long-term use.

The release agent production process adopts a computer-controlled fully automated emulsification and feeding production line, and the filling adopts electronic quantitative filling, which ensures the stability of the entire production process and the accuracy of filling. Each barrel of product can be traced back to the raw material and process according to the batch number, and can be traced back to the batch number information of each raw material used in the production process, to determine the stability of the product and the traceability of the production process, leading the industry Level.

Even after many days in use, no sticky residue will form on die and frame, pipes of spray systems and nozzles will never block. Core slides and vents will stay clean, allowing air and gas to escape unhindered thus improving the quality of castings (reduced porosity).

Properties And Advantages

● Castings are well suitable for joining processes like welding and glueing

● Excellent paintability and powder coating ability of castings

● Tried and tested on conventional, reduced, as well as micro-spraying

● Good die release and good lubrication of ejector pins

● Effective reduction of "metallization" (metal-on-metal welding) ,excellent and shiny surfaces of castings

● High process reliability (stable emulsion, no separation, no stirring required) ,clean die frame and environment; no clogging of pipes and spray nozzles

Application

Suitable for a wide spectrum of castings,also for large structural and heavy parts. Die temperatures:from about 130 to 380 °C.

It is more suitable to be used for automotive parts, or those who have high requirements for carbon build-up, or those who want to replace the performance of international brands.

The ultimate or ideal dilution ratio for a particular casting is determined by: duration of spray, spray velocity, geometry and complexity of casting as well as the temperature of the tooling. On-site tests should therefore be carried out to establish the correct ratio for each particular application.

Recommended dilution ratios with tap water

Product Aluminium and Magnesium

RLT-8810: 1 : 100-120

RLT-8820: 1 : 250-300

RLT-8850: 1 : 400-500

RLT-8850 are available in several concentrations, each of them will dissolve in water instantly. Prior to use, RLT-8850 must be diluted with water. Thereafter the diluted product should not be stirred in order to prevent foaming. Do not use air agitation. Immediately after use, the containers with the release agent concentrate must

be closed tightly.

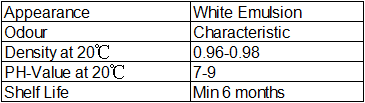

Chemical And Physical Data

Contact: LilyLu

Phone: +86 138 2603 0637

E-mail: lilylu@rolitom.com

Whatsapp:+8613826030637

Add: Room610 NO.1 XiangPu Street,TianHe District,Guangzhou City,china

We chat